RESEARCH PROJECT CASE STUDIES

Servitisation

Background:

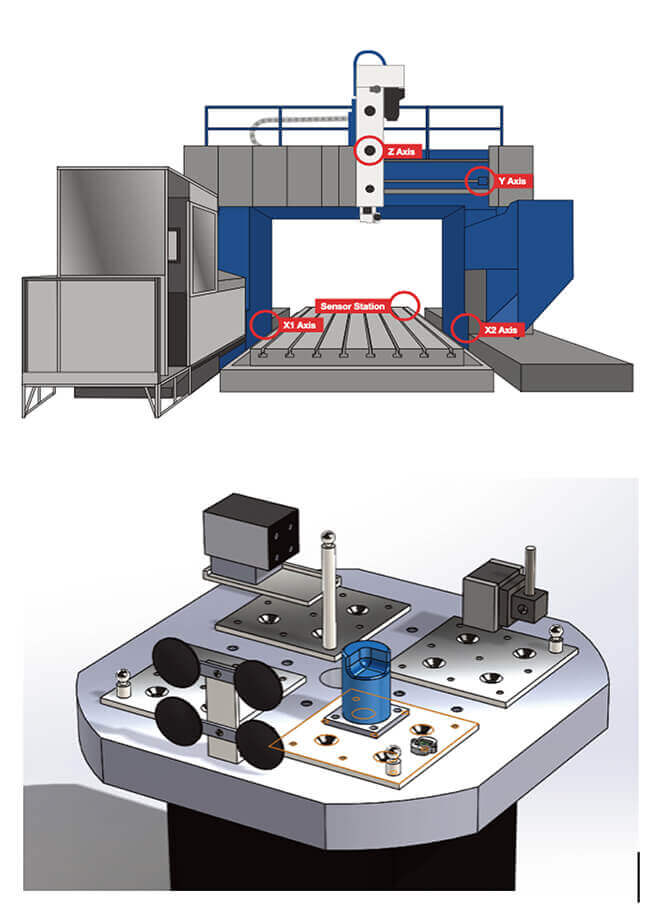

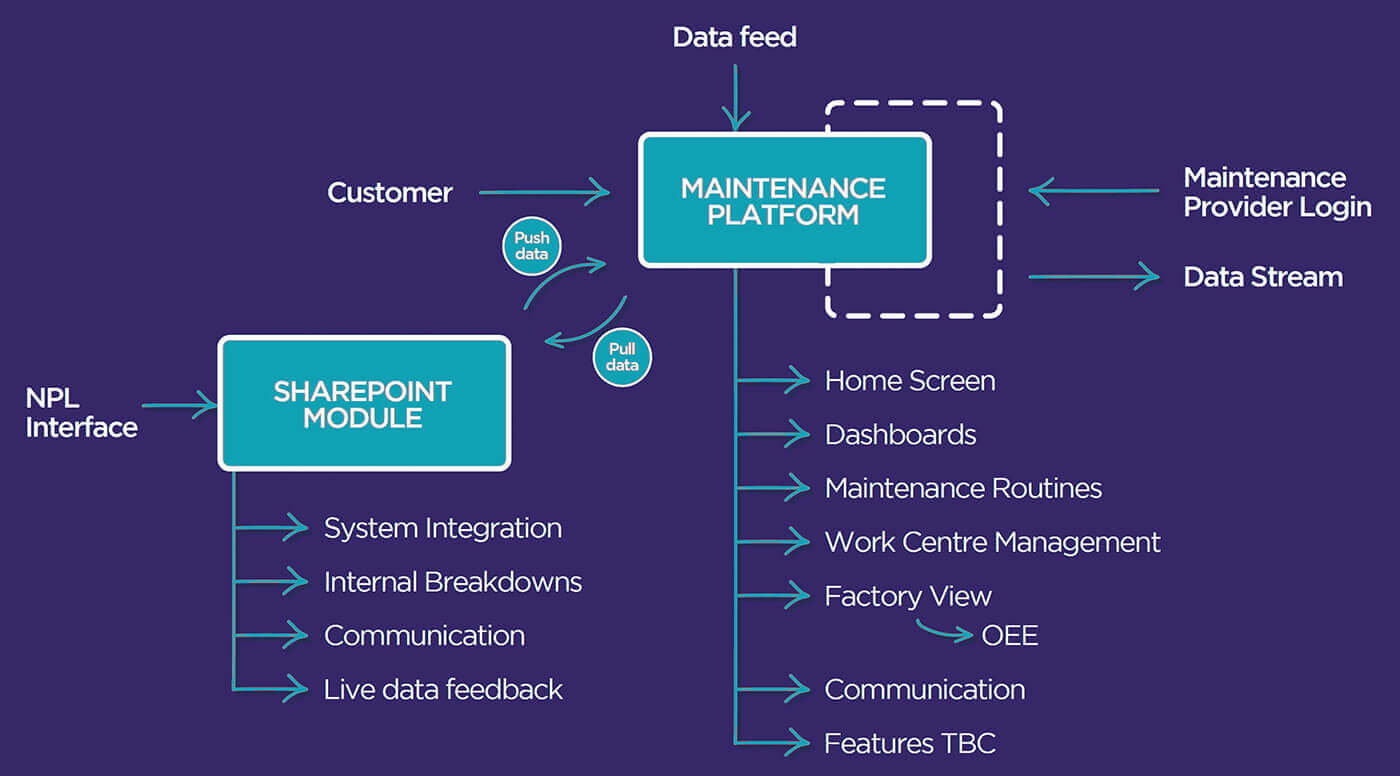

Tower DMS are the software partners in a consortium delivering a UK Innovate project to fully servitise a precision engineering factory.

This is a collaboration between several universities and industry partners and covers all aspects of automating machine maintenance between the shop floor and management systems.

What is servitiation?

Servitisation of machine tools is a concept where manufacturers purchase productive time available on a machine, rather than the capital asset.

Servitisation has been implemented successfully in production lines, tooling supply and most notably Rolls-Royce aero engines which are almost exclusively supplied to their clients based on a servitisation model.

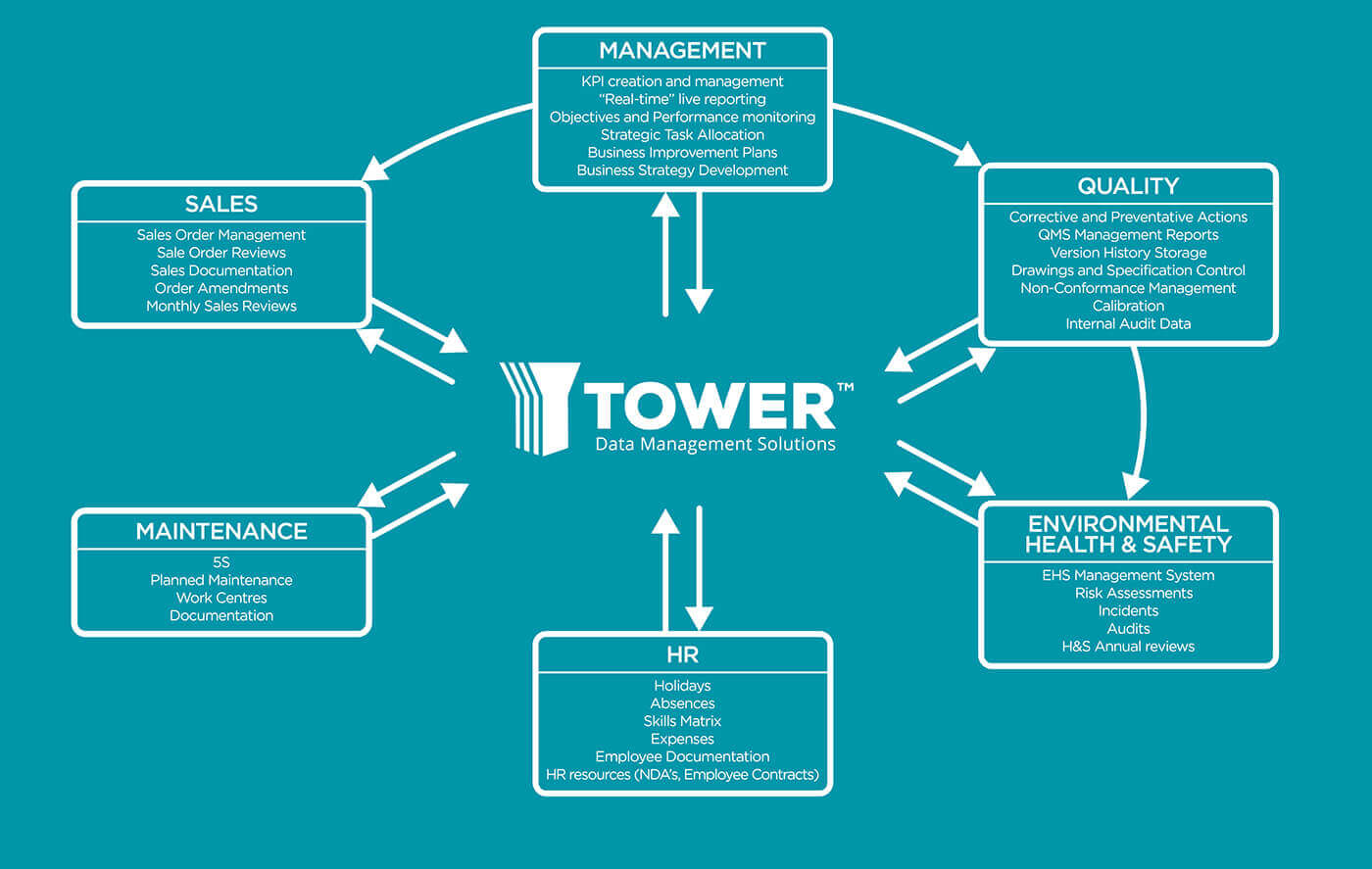

Tower DMS

Tower DMS developed a solution to capture and visualise the live data collection from the factory machines using integrated data analytics for the factory floor.

Commercial Projects

NAMRC IMS (Integrated Management System)

An ongoing project to create a fully integrated management platform for the Nuclear Advanced Manufacturing Research Centre.

It will eventually encompass all of the requirements to achieve and operate within the relevant nuclear quality standards, setting the benchmark for industry.

This system comprehensively manages the business development activities of the NAMRC and integrates these with project delivery and performance review within the context of Quality Assurance.

NQA-1 Management Platform

Over the last 18 months Tower has worked with Nuclear Energy Components to create a fully integrated management platform to NQA-1 standard – the most stringent nuclear requirements in the industry. This has contributed to their ongoing business development and securing a significant amount of further work with a number of high profile nuclear customers.